Car cleaning agent - as an early maintenance product, in the car beauty shop, the staff will use the car cleaning agent. Car cleaning agent can not only clean the dust on the surface of the car body, but also form a film to protect the car paint. However, during the production process of car cleaning agents, excessive foam will be produced, which will seriously affect the product quality, slow down the production efficiency, and even cause pollution to the surrounding environment. The occurrence of these series of problems has made manufacturers helpless. But at this time, fortunately, there are car cleaning agent defoamers, which can solve this problem for manufacturers.

Car cleaning agent - as an early maintenance product, in the car beauty shop, the staff will use the car cleaning agent. Car cleaning agent can not only clean the dust on the surface of the car body, but also form a film to protect the car paint. However, during the production process of car cleaning agents, excessive foam will be produced, which will seriously affect the product quality, slow down the production efficiency, and even cause pollution to the surrounding environment. The occurrence of these series of problems has made manufacturers helpless. But at this time, fortunately, there are car cleaning agent defoamers, which can solve this problem for manufacturers.- 5月 08 週三 202415:59

Car cleaning agent defoamer

Car cleaning agent - as an early maintenance product, in the car beauty shop, the staff will use the car cleaning agent. Car cleaning agent can not only clean the dust on the surface of the car body, but also form a film to protect the car paint. However, during the production process of car cleaning agents, excessive foam will be produced, which will seriously affect the product quality, slow down the production efficiency, and even cause pollution to the surrounding environment. The occurrence of these series of problems has made manufacturers helpless. But at this time, fortunately, there are car cleaning agent defoamers, which can solve this problem for manufacturers.

Car cleaning agent - as an early maintenance product, in the car beauty shop, the staff will use the car cleaning agent. Car cleaning agent can not only clean the dust on the surface of the car body, but also form a film to protect the car paint. However, during the production process of car cleaning agents, excessive foam will be produced, which will seriously affect the product quality, slow down the production efficiency, and even cause pollution to the surrounding environment. The occurrence of these series of problems has made manufacturers helpless. But at this time, fortunately, there are car cleaning agent defoamers, which can solve this problem for manufacturers.- 11月 02 週四 202316:09

Three Ionic States of Polyacrylamide

PAM structural differences

- 11月 02 週四 202316:08

The Polyacrylamide in China

Polyacrylamide production in China is significant, and the country is one of the leading producers and consumers of polyacrylamide globally. China has a well-established chemical industry and a large market demand for polyacrylamide due to its wide range of applications.

Several factors contribute to China's prominence in the polyacrylamide industry:

Several factors contribute to China's prominence in the polyacrylamide industry:

- 11月 02 週四 202316:04

Water Treatment Flocculant Polyacrylamide

Water treatment flocculants are chemical substances used to aid in the removal of suspended solids, organic matter, and other impurities from water during the clarification or filtration process. These flocculants promote the aggregation of fine particles into larger, settleable flocs, making it easier to separate them from the water.

Here are some commonly used types of flocculants in water treatment:

Here are some commonly used types of flocculants in water treatment:

- 8月 22 週二 202314:59

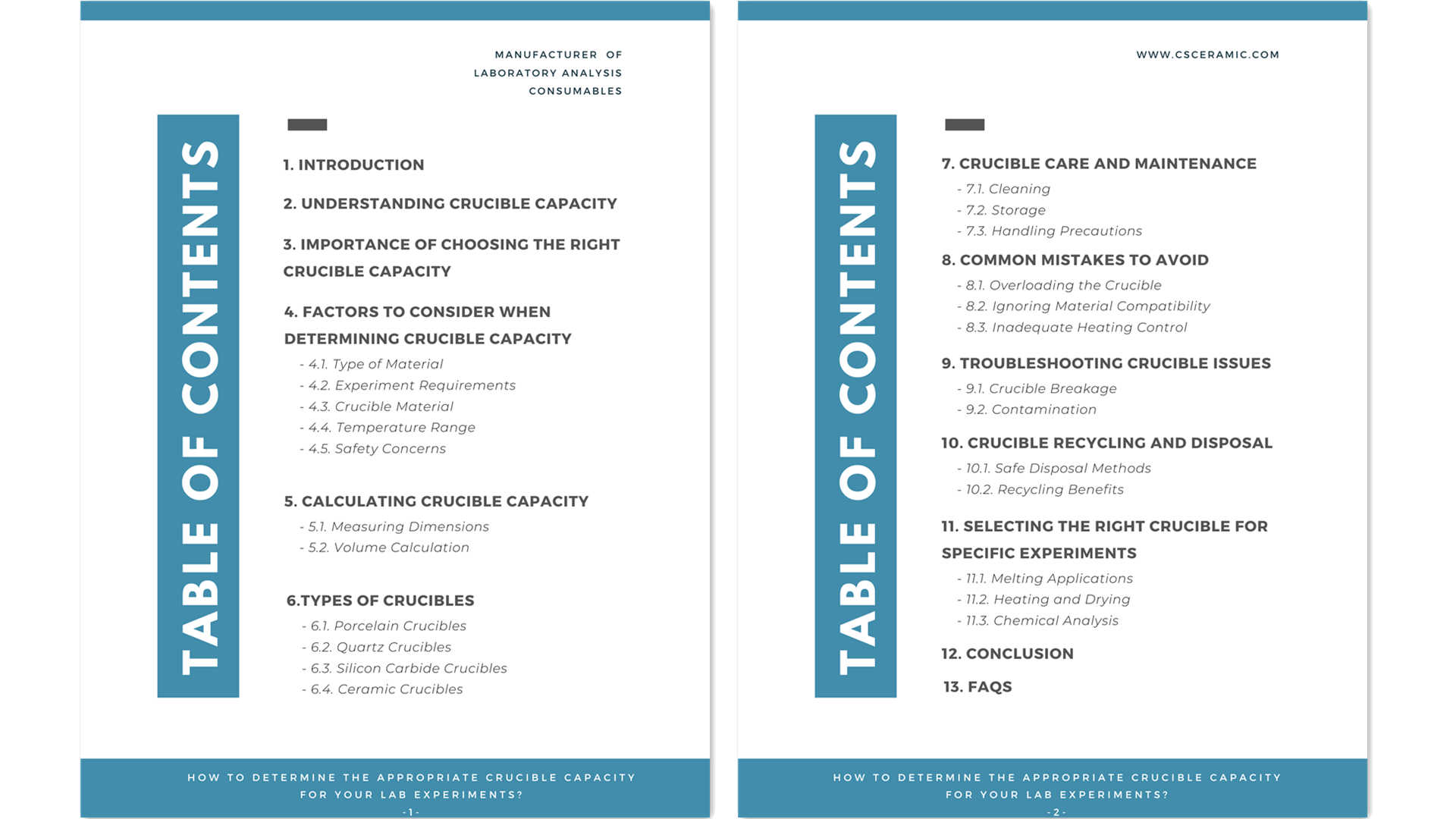

Determine the Crucible Capacity for Lab Experiments

How to Determine the Appropriate Crucible Capacity for Your Lab Experiments?

How to Determine the Appropriate Crucible Capacity for Your Lab Experiments?- 8月 22 週二 202314:59

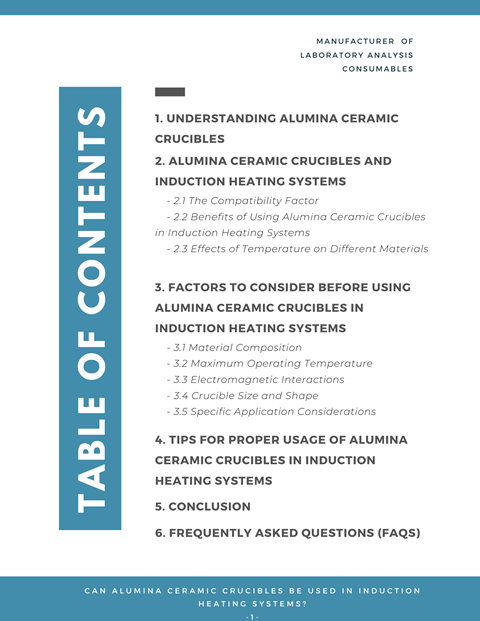

Alumina Ceramic Crucibles Used In Induction Heating Systems

Can Alumina Ceramic Crucibles be Used in Induction Heating Systems?

Can Alumina Ceramic Crucibles be Used in Induction Heating Systems?- 8月 22 週二 202314:58

Optimize Milling Efficiency: Choosing Ideal Grinding Media

Choosing the Right Grinding Media for Enhanced Milling Efficiency

Choosing the Right Grinding Media for Enhanced Milling Efficiency- 8月 22 週二 202314:57

Are Al2O3 Crucible Suitable for Melting Precious Metals?

Alumina Ceramic Crucibles Used For Melting Precious Metals

Alumina Ceramic Crucibles Used For Melting Precious Metals- 6月 08 週四 202311:01

Waterborne Polyurethane For Architecture Waterproof Coating

Waterborne polyurethane is an environmentally friendly coating material with excellent waterproofing properties, which can be widely used in roof waterproofing projects. Its main applications are as follows:

Roof surface coating: Waterborne polyurethane can be used as a coating material for roof surfaces, forming a strong and durable waterproof membrane that effectively prevents water penetration and leakage problems.

Roof surface coating: Waterborne polyurethane can be used as a coating material for roof surfaces, forming a strong and durable waterproof membrane that effectively prevents water penetration and leakage problems.

- 6月 08 週四 202310:53

Water-Based Polyurethane Binder(WPU)

Polyurethane (PU) is a versatile polymer material that has a wide range of applications in various industries. One of the most popular applications of PU is in the textile industry, where it is used as a binder for textile printing, lamination, and surface treatment.

Polyurethane (PU) is a versatile polymer material that has a wide range of applications in various industries. One of the most popular applications of PU is in the textile industry, where it is used as a binder for textile printing, lamination, and surface treatment.One of the most significant advantages of using PU as a binder for textile printing is its water-based nature. This makes it an eco-friendly and sustainable alternative to traditional solvent-based printing methods. Additionally, the use of water-based PU in textile printing reduces the amount of volatile organic compounds (VOCs) that are released into the air, which is particularly important for indoor printing applications.